Your Fastest Path

to Efficient

Performance

Slash defects, ramp up efficiency, and turbocharge planning across all your production sites, all from one game-changing platform.

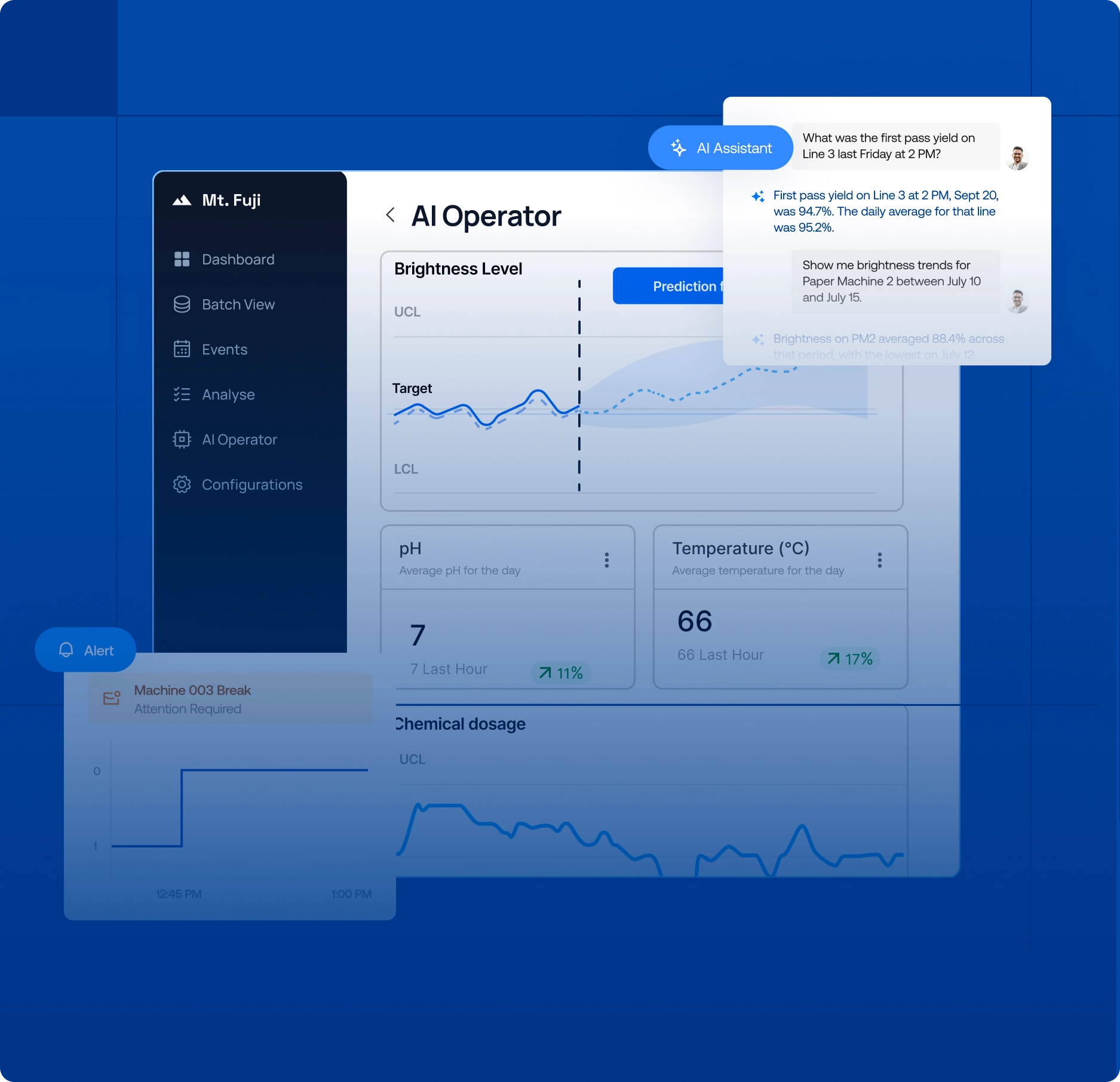

Experience Mt. Fuji: Your Plant, Smarter in Seconds

Unleash AI

Unleash AI

Boost Efficiency

Boost Efficiency

Secure Data

Secure Data

Faster Insights

Faster Insights

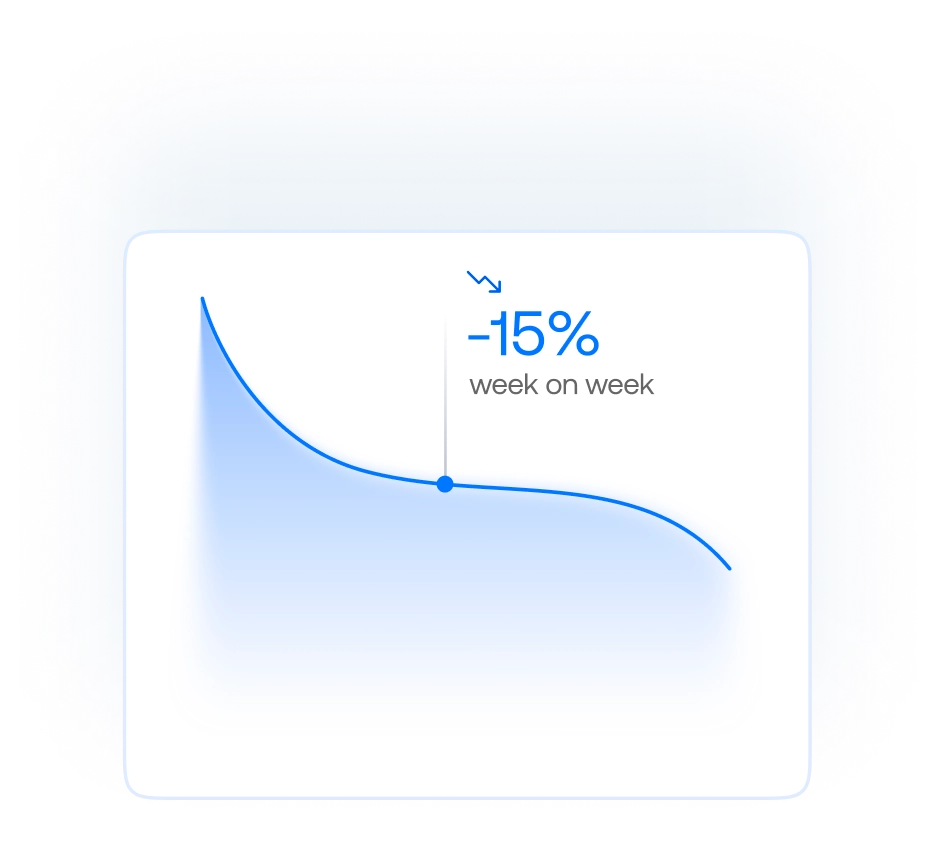

15%

yield improvement within 6 months

35%

unplanned downtime per year

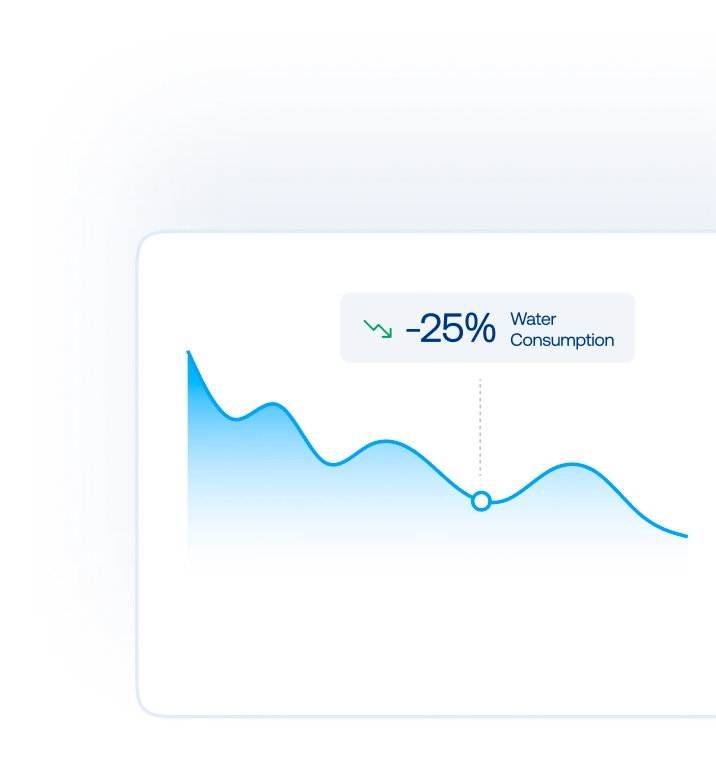

25%

reduction in rejects

50-60%

fewer paper breaks

6 Months

payback period

3 Weeks

operator adoption tenure

zero disruption to production

Mt.Fuji for everyone

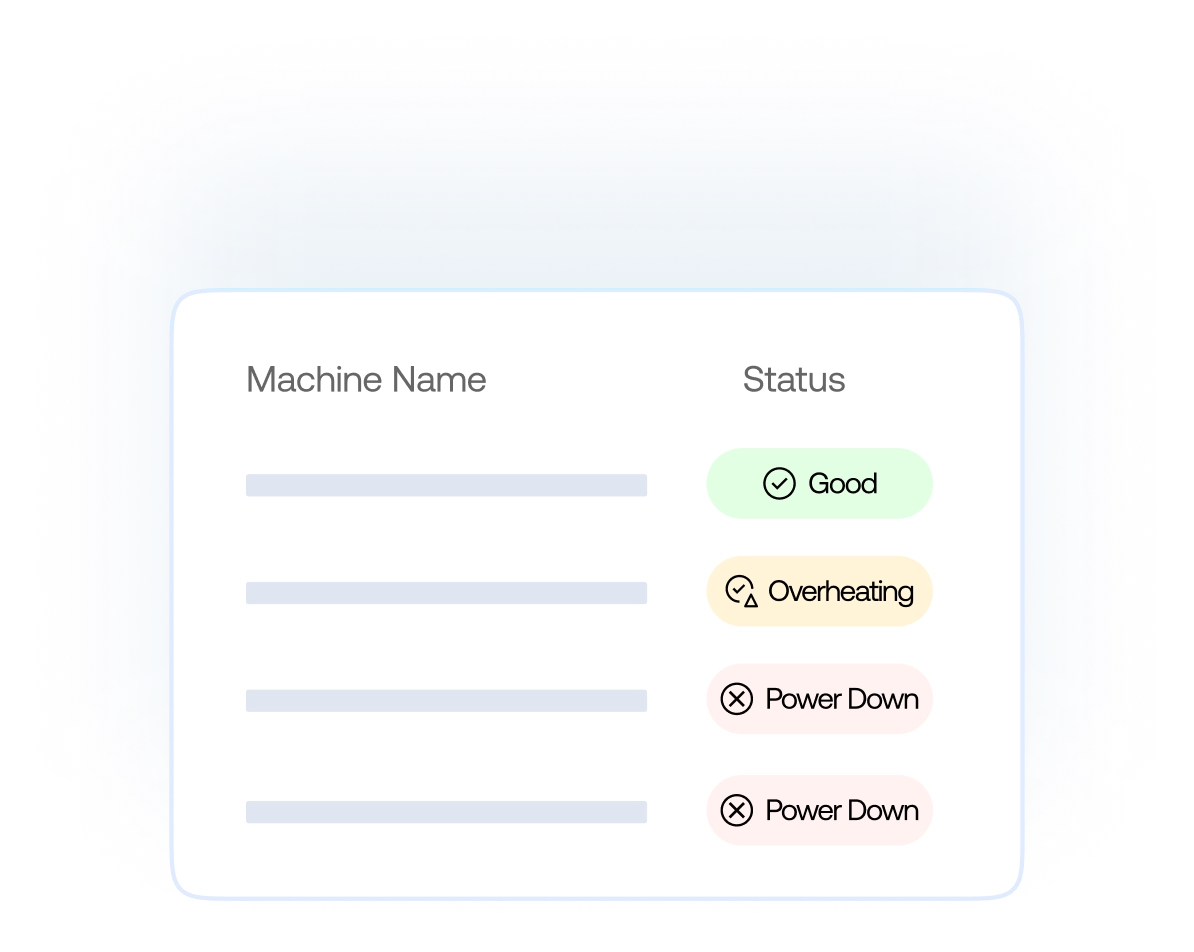

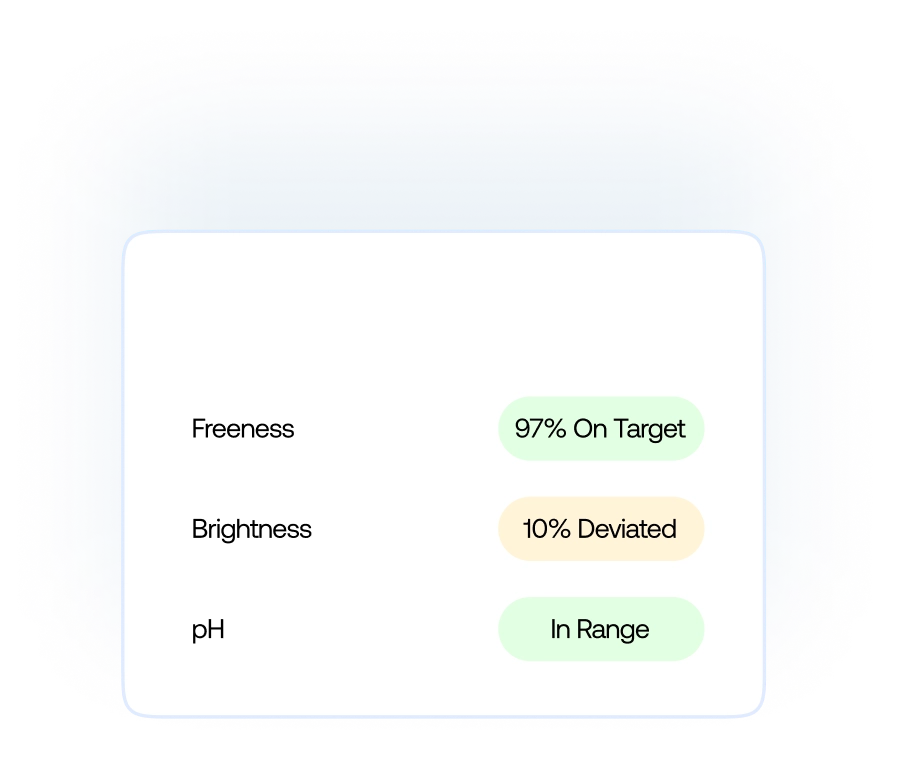

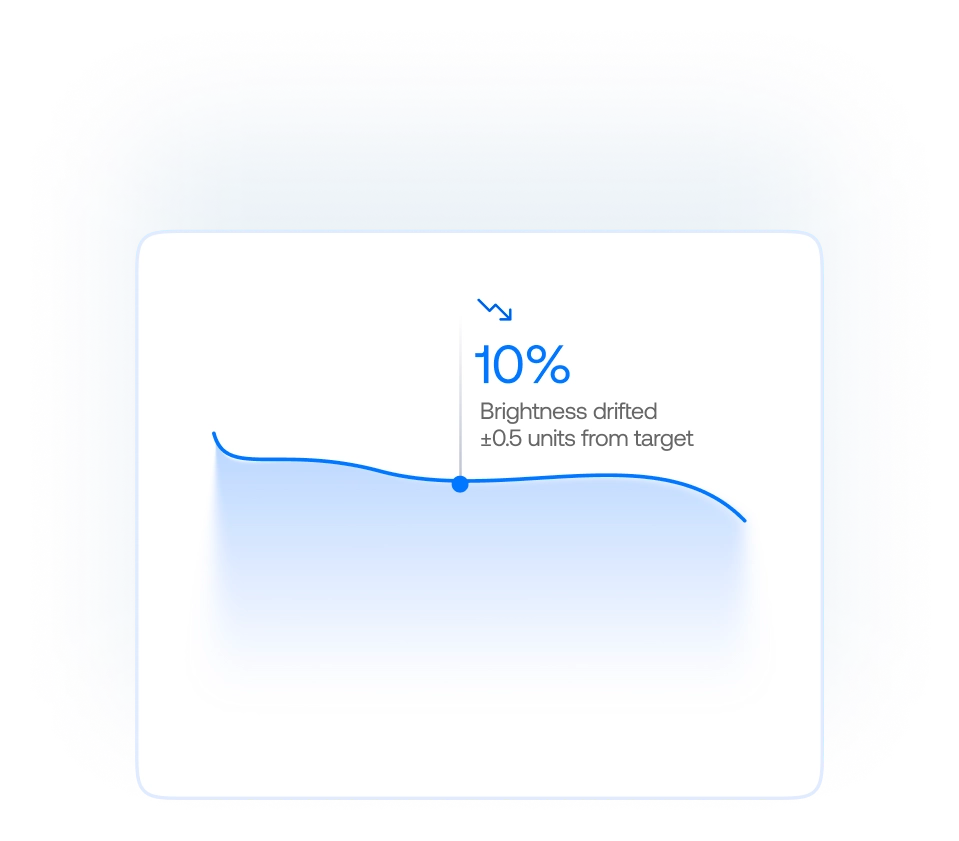

Gain real-time process visibility and automated AI-driven adjustments to correct deviations when they happen.

Mt. Fuji connects plant-level OT systems (like PLCs, SCADA) with enterprise IT systems (MES, ERP, shift logs) on one secure unified platform.

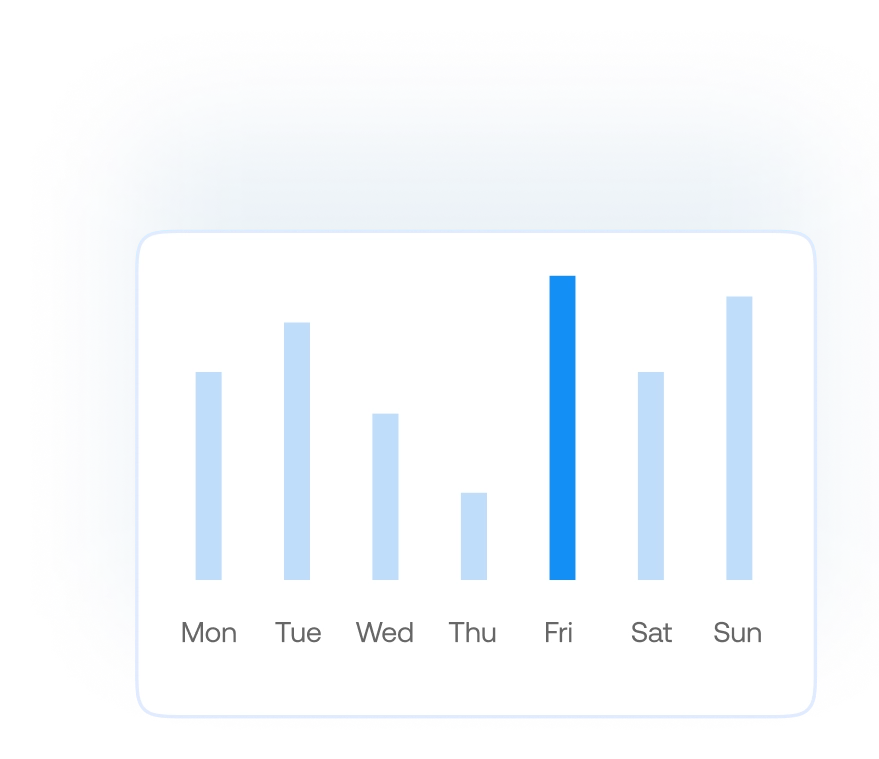

Achieve high visibility across sites for yield, efficiency, and asset performance.

Mt. Fuji helps minimize scrap, reduce rework, and avoid poor production runs, by improving first-passage yield and consistency of batch quality.

Gain instant access to clean, contextualized, and ready-to-use production data from multiple sources.

CASE STUDIES

Real Results,

Proven Impact

CASE STUDIES

Real Results,

Proven Impact

TESTIMONIALS