AI-Powered

Productivity for

Pulp, Paper,

Tissue & Packaging

Boost consistency, reduce variability, and maximize fiber use with AI tailored to the pulp, paper & packaging industry.

The Hidden Cost of Inconsistency

At paper and packaging, raw material fluctuations, energy costs, and quality pressures never stop. Even small process variations, from pulping to drying, can trigger rejects, excess trim loss, and costly downtime. Staying consistent under constant variability is the industry’s toughest challenge.

AI That Understands Paper

Haber combines deep paper-industry expertise with advanced AI to stabilize operations, optimize every run, and eliminate waste.Our platform continuously learns, predicts, and acts — keeping your mill efficient and future-ready.

Deliver consistent sheet quality, shift after shift

Minimize trim loss and maximize fiber yield

Respond to process deviations faster

At least 22%

Increase in Revenue

Up to 34%

Savings in Raw Materials

Over 30%

Faster process correction

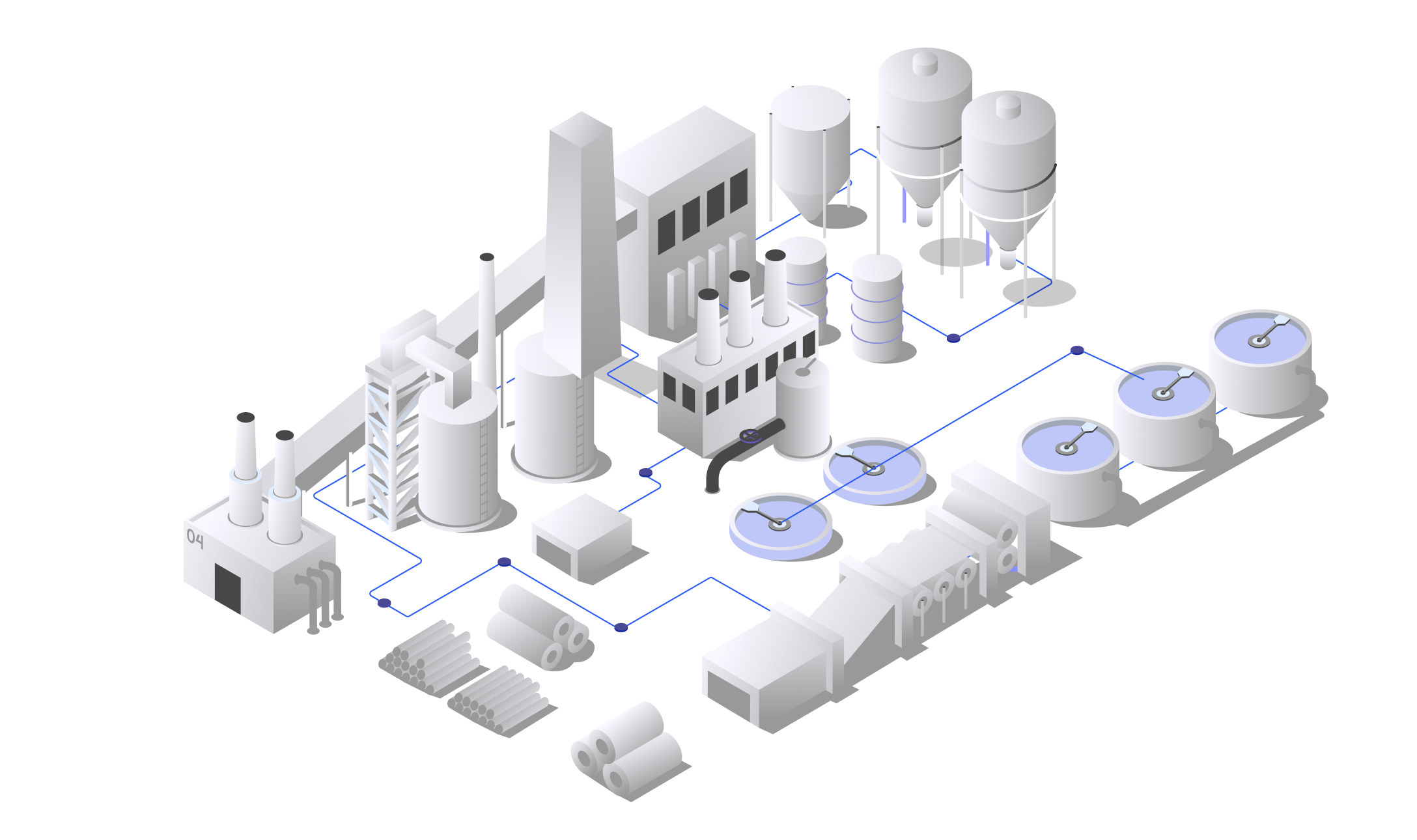

Present across the plant

Pulp Mill

Chemical Recovery

& Utilities

Water & Wastewater

Management

Paper Machine

CASE STUDIES

Real Results,

Proven Impact

CASE STUDIES

Real Results,

Proven Impact

TESTIMONIALS